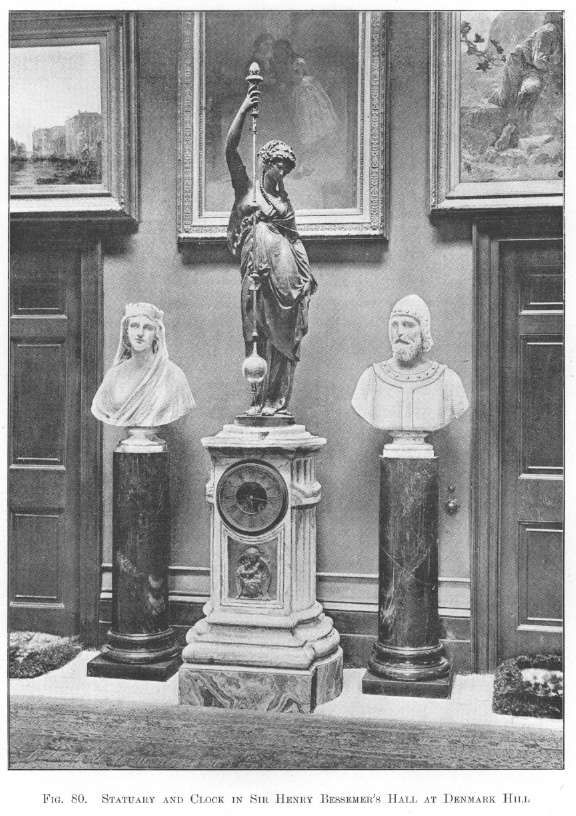

journey. They are at present (1896) in good company, for between them stands a massive pedestal, 4 ft. high, made of Algerian onyx, forming the base of a large Parisian clock, with a life-sized bronze figure holding a revolving pendulum. The serpentine columns support busts of Enid and Prince Geraint from the "Idylls of the King," sculptured in white Carrara marble. This group stands on one side of the entrance-hall of my residence (see Fig. 80, Plate XXXVI).

On my return to London a plain, business-like review of all the circumstances connected with the supply of manganese ore from Cornwall was unsatisfactory. My old friend Galloway was getting on in years, and not over-anxious to embark in new undertakings, while the pursuit of my own business, and the spread of the process throughout Europe, engrossed my whole attention. Thus time rolled on; we made shift with Franklinite, which was 40 per cent. richer in manganese than spiegeleisen, but it was not all we could desire. A little later, it occurred to me that oxide of manganese was a waste product in the manufacture of chlorine and bleaching powder, and I knew that the firm of Tennant and Co., of St. Rollox, Glasgow, were most extensive manufacturers of this article. At that time Mr. Rowan, of Glasgow, was making Bessemer steel under a license from me, and I wrote to him saying that I was coming down to Glasgow, and hoped that he would be able to get me an introduction to Messrs. Tennant. In reply, Mr. Rowan invited me to come to his house and stay a week. I did so, and, in talking over the matter, he said: "I know a Mr. Henderson, who is a good chemist, and is carrying out a scheme of his own at the works of Messrs. Tennant and Co., where he is operating on iron pyrites, and one of his waste products is pure iron in the form of powder. I will, if you wish it, ask him to come and dine with us to-morrow."

The next evening I explained to Mr. Henderson how I proposed to manufacture an artificial metallic ore, consisting of iron and manganese, by combining hematite, or white carbonate of iron, with oxide of manganese, in equal proportions. These materials were to be held together with clay, or with clay and lime, to form a fluid cinder, either with or without the addition of carbonaceous matter. I proposed to mix these materials in a common brickmaker's pug-mill, to dry the mixture in moderate-sized lumps, and to convert this artificial ore into the metallic state in an ordinary blast furnace. I told Mr. Henderson that I wanted some large firm to take up the manufacture, as I had no time to attend to it, and did not wish to make such manufacture a source of profit. All I wanted was to be supplied with a manganesian alloy of iron, of not less than 50 per cent. of manganese, for my own use and that of my licensees, who would most assuredly become large purchasers. Mr. Henderson was very anxious to take the matter in hand, but he feared to encounter the large cost of erecting a complete blast furnace plant. He said that he had no doubt he could produce the alloy in a less expensive furnace, and was willing to risk the cost and trouble of doing so. I, on my part, gave up the idea of pressing it upon Messrs. Tennant, as I originally intended, and left the whole matter in Mr. Henderson's hands. The result of this was that he took out a patent for manufacturing these rich manganese alloys in a reverberatory gas-furnace, and so far succeeded as to produce alloys containing from 20 to 25 per cent. of manganese, with which he supplied our Sheffield firm until his works were, unfortunately, closed, owing to the insolvency of the iron-founder on whose premises his furnace was erected.

Thus was inaugurated the manufacture of ferro-manganese, the production of which I had followed up as closely as my many engagements permitted, from the very first inception of the idea, dating from the reading of a chapter on steel in Dr. Ure's Dictionary of Arts and Manufactures; followed by the perusal of Heath 's patents, and the evidence of the Sheffield steel-manufacturers given in one of Heath's law suits, as published in Webster's Law Reports. I never lost sight of the object, so successfully arrived at, which would have been attained long before had not the inferior alloy, spiegeleisen, been an article of commerce at once procurable; this delayed the production of an alloy specially suitable for the purpose. But, valuable as this ferro-manganese really was, neither that, nor spiegeleisen, could make good steel from the ordinary quality of pig iron used for the manufacture of iron bars, nor from the hematite iron as then made, since the hematite pig iron, like all other British pig, was greatly contaminated with phosphorus, owing to the use of puddler's tap cinder to flux the hematite ore in the blast-furnace, and thus obtain a fluid cinder. It was not until I had, with the assistance of my own chemist, prescribed new furnace charges, omitting tap cinder and substituting shale, and thus producing Bessemer pig, that any British coke-made iron could be converted by my process into good steel. The universal presence of phosphorus

| Previous chapter/page | Back | Home | Email this | Search | Discuss | Bookmark | Next chapter/page |