of 12-, 18-, and 24-pounders, forged, and ready for the boring mill, at £45 per ton, a price about three times their actual cost, but still very considerably below that of crucible steel forgings.

I may here mention that every gun, after being forged by our firm, had its quality tested in the following simple and practical manner. The gun when being forged had a part of both ends drawn down under the hammer, into a flat bar of some 12 in. or 15 in . in length and 3 in. wide by 2 in. in thickness -- this was our standard test. A gun so forged is shown in the annexed engraving, Fig. 67.

In this illustration the view A shows the gun with these test pieces still projecting from each end; they were cut off and bent, when cold, into the form shown in A, while B shows the gun-block ready to be turned and bored.

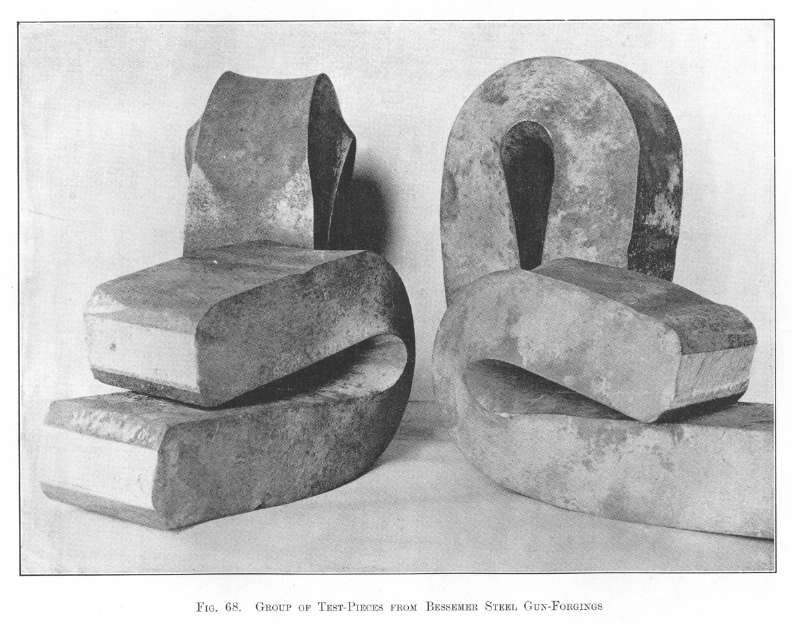

A group of these test pieces is reproduced to a scale of half the actual size in Fig.68, Plate XXVII., and this engraving prepared from a photograph - clearly shows how wonderfully these pieces bore the enormous strain due to the cold bending of so large a mass, the metal in each case bulging out laterally on the inside of the bend, and contracting in width on the outside of it, thus supplying the material forming the greater length of the outer surface. Notwithstanding this interchange of parts, not a sign of tear or breaking is visible in any one of their sharply-defined angles.

Mr. A. L. Holley's remarks on our steel guns, published in his book on Ordnance in 1863, are subjoined, and form an independent testimony to their value.

141. Bessemer Steel Guns. -- The Bessemer process of making steel direct from the ore, or from pig- iron, promises to ameliorate the whole subject of Ordnance and engineering construction in general, both as to quality and cost. This product has not yet been used for guns to any great extent, although Mr. Krupp, the leading steel-maker, has introduced it. Captain Blakeley and Mr. Whitworth have also experimented with it, and expressed their faith in its ultimate adoption. Messrs John Brown & Co., Sheffield, have made over 100 gun-forgings, some of them weighing above 3 tons, from solid ingots of this steel. During the present year, their production of Bessemer steel will exceed 400 tons per week. With the two new converting vessels then in operation, solid ingots of 20 tons weight can be fabricated. A large establishment about to be started in London, with a 50-ton hammer, and a capacity to pour 30-ton ingots, will afford the best possible facilities for the development of this process.

As a point of special interest in connection with the paper I was going to read at the Sheffield meeting of the Institution of Mechanical Engineers, I detemined to take strict account of the time occupied in making, at my steel works, an 18-pounder gun, and to put the finished weapon on the table in front of the Presidential chair. By this means the Superintendent of the Royal Gun Factory at Woolwich could not help being placed in possession of all the facts and arguments I was going to put forward in my paper, and which I intended should be illustrated with plenty of actual specimens. I have reproduced here pages 144 and 145 from the published Proceedings for 1861 of the Institution of Mechanical Engineers, in order to show what words Sir William Armstrong actually heard, and what facts were brought to his knowledge at that meeting, and also what mechanical proofs of the marvellous toughness of Bessemer mild steel were placed on the table immediately in front of him.

The special aim of the author during the first year of his labours, which throughout the last six years has never been lost sight of, was the production of a malleable metal peculiarly suitable for the manufacture of ordnance. By means of the process that has been described solid blocks of malleable cast steel may be made of any required size from 1 to 20 or 30 tons weight, with a degree of rapidity and cheapness previously unknown. The metal can also with the utmost facility be made of any amount of carburation and tensile strength that may be found most desirable: commencing at the top of the scale with a quality of steel that is too hard to bore and too brittle to use for ordnance, it can with ease and certainty be made to pass from that degree of hardness by almost imperceptible gradations downwards towards malleable iron, becoming at every stage of decarburation more easy to work and more and more tough and pliable, until it becomes at last pure decarbonised iron, possessing a copper-like degree of toughness

| Previous chapter/page | Back | Home | Email this | Search | Discuss | Bookmark | Next chapter/page |