the Bessemer process. The apparatus for this was put up at their works last year, and they we now greatly extending their field of operations by putting up more powerful apparatus at their blast furnaces in the Landes. There are also in course of erection, four other blast furnaces in the South of France, for the express purpose of carrying out the new process. The long and well-earned reputation of the firm of James Jackson and Son is in itself a guarantee of the excellent quality of the steel produced by this process. The French samples of bar steel exhibited were manufactured by this firm. Belgium is not much behind her neighbours in the race, as the process is being put in operation at Liége. While in Sardinia preparations are being made to carry it into effect, Russia has sent to London an engineer and a professor of chemistry to report on the process, and Professor Muller, of Vienna, and M. Dumas and others, from Paris, have visited Sweden to inspect and report on the new system in that country.

These facts will serve to show how, on the Continent of Europe, the fame of this new metal was spreading, and its manufacture extending. It will be seen from the foregoing that Colonel Wilmot fully corroborated what I have previously stated, and gave the results of some experiments of his own with a mass of iron he happened to see lying with other waste scrap at my works at Sheffield. This mass of iron (see page 196 ante) he desired to be sent to Woolwich, and from it were cut the two cylindrical pieces which he described to the meeting; he proved that Bessemer pure iron, only slightly hammered, showed in the proving-house a tenacity of 64,426 lb., or 28.76 tons per square inch.

Another year or more slipped away, almost unnoticed in the ardour and excitement created by the rapid development and progress of my invention. Our own works were crammed with orders for locomotive double-throw cranks, which had hitherto been exclusively made at Lowmoor, or at some other of the justly-celebrated Yorkshire ironworks, but which were now being constructed of Bessemer steel. We were also busy with plain engine and carriage axles, marine engine and screw-propeller shafts, steel guns and gun blocks, locomotive engine and carriage tyres, etc. Our works were daily engaged in superseding welded Lowmoor tyres, and we were turning out, as fast as the mills could roll them, mild steel weldless tyre-hoops from 4ft. 6in. to 5ft. in diameter, to be shrunk on to locomotive engine driving-wheels, and also 3ft. tyres for carriage wheels, of which many thousands were ceaselessly running on our railways. All these hoops were tightly shrunk on to the wheels with a firm grip, just in the same manner as hoops are shrunk on to built-up guns. These thousands of hoops were daily responsible for the lives of tens of thousands of passengers seated immediately above them. Every train of twenty-five carriages would have a hundred of these steel tyres supporting their heavy load of wood and iron, and their still more valuable living freight, rushing over the steel rails at a high speed, and tending, by their rolling motion and heavy pressure at a single point of their circumference on the steel rail, to become elongated and loosened from the wheel, a tendency which this strong elastic steel most successfully resisted. It must be borne in mind that the loosening of this firm grip on only one of these hundred hoops, or the fracture of any one of them, might have wrecked a whole train, and killed more people than the bursting of a gun -- an instrument that may be required to do duty for a few hours, at intervals of many years, or, perhaps, never be used at all. That these thousands of Bessemer steel tyres did not fail in constant service, and did not lose their grip upon the wheels, furnished no proof to those obtuse intellects who could only recognise the virtues of welded iron. Bessemer steel hoops, so extensively used with the full sanction of the eminent engineers of our British railways, found, however, no favour at Woolwich or at Elswick. They were, nevertheless, employed by Captain Blakeley, the original inventor of built-up guns, and also by the Blakeley Ordnance Company of London, for the manufacture of built-up guns which were being made for Russia, and other foreign governments, while Woolwich and Elswick were rapidly manufacturing welded iron guns with welded iron hoops, for home use.

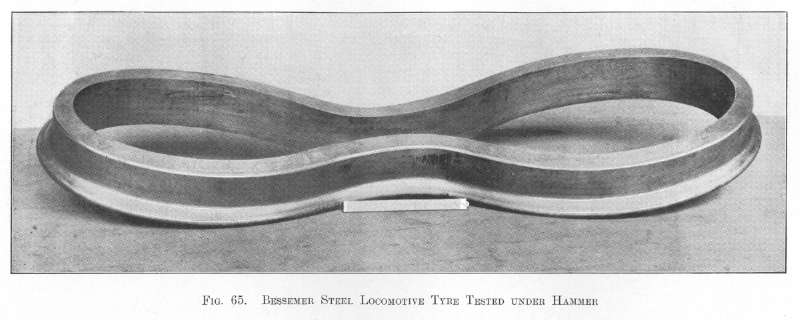

As a practical proof of how far weldless steel tyres would resist fracture under the most severe trials, a locomotive engine-tyre, turned and finished, was placed up on edge under a steam hammer, and received blow after blow until its two opposite sides touched each other, when its elasticity again allowed it to spring back a few inches. This large tyre was thus formed into a long flat loop (see Fig. 65, Plate XXVI., in which its dimensions are indicated by the foot-rule lying in front of it).

| Previous chapter/page | Back | Home | Email this | Search | Discuss | Bookmark | Next chapter/page |