cast-iron roller working in the open air is not a thing to which one can apply the glass bulb of a thermometer, and ascertain the precise temperature of its external surface; consequently, the accurate control of the temperature of the roller presented many difficulties; but, after some study of the question, I found a most satisfactory way of ascertaining this all-important fact.

I was aware that metallic lead fuses at a temperature of 640 deg. Fahr., and by additions to that metal of tin and bismuth, in varying proportions, its melting temperature can be lowered until the alloy will fuse at the boiling point of water, viz., 212 deg. With these facts before me, I had simply to form a standard alloy, fusible at, say, 450 deg. Fahr., that being the required temperature of the roll. This we may call alloy B; another alloy, A, was made that would fuse at 10 deg, lower than B, and a third, C, was made whose melting temperature was 10 deg. Fahr. higher than B. These three alloys were made into rods about the length and size of a black-lead pencil. Their use was extremely simple. When commencing to heat up the roller for working, one end of the most fusible rod, A, was pressed against the hot iron roller as it revolved, and as soon as the first symptom of the fusion of the end of the rod manifested itself, it was known that the roller was within 10 deg. of its proper working heat. Care was then taken to gradually regulate the gas supply, and when the end of the standard or working rod B was found to fuse on being pressed against the roller, the machine was put in motion at the exactly ascertained speed, thus producing with certainty a beautiful figured fabric that twenty years after would be found in much the same condition, less the amount of wear and tear to which it had been subjected.

The first practical working of this new process was upon a beautiful design, for which Messrs. Pratt had obtained an order for furnishing a suite of apartments at Windsor Castle, so that the new material, under so favourable an introduction, was certain to become fashionable.

In those palmy days of Utrecht velvet embossing, I was paid six shillings a yard for putting fabric through the rolls; but gradually this very high price was reduced, and when it came down to a shilling per yard immense quantities were embossed. Prices were still on the decline, when my machines and the stock of engraved rollers were purchased from me by Messrs. Gillett, Lees and Company, the well-known Utrecht velvet weavers of Banbury. A general taste for this material soon afterwards set in; prices for embossing were lowered ultimately to one penny per yard, and many persons may still remember, some forty years ago, seeing the cushions of cabs and omnibuses covered with this decorative fabric. It is curious that the present fashion for antiquated furniture has again brought it into use, and it may now be seen in many of the best houses.

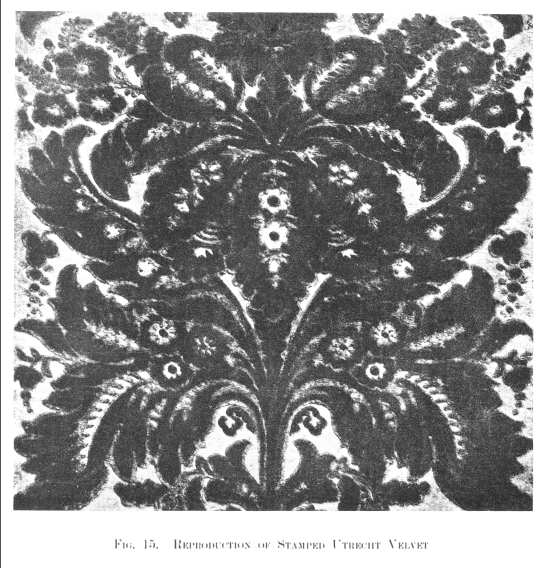

The original specimen of figured Genoa Velvet brought me by Mr. Pratt had what is called a narrow edging of "Terry," or uncut velvet, forming a series of little ribs which surrounded each leaf or scroll in the design, and made a sort of natural shading between the dark untouched pile of velvet, and the bright and satiny pressed-down surface of the ground on which the design was formed. A very beautiful specimen of my imitation of this "Terry" edging came into the possession of my niece, Mrs. Ada Alien, of Wingerworth Hall, and this she kindly presented to me; it has some historic interest, being the design of Mr. Pugin for covering the benches in the House of Lords; the roller was engraved by myself, and it was the first attempt to produce an imitation of the "Terry" edging in this new fabric. A photographic reproduction of this old specimen is given in Fig. 15, Plate VII., and it shows that after the many years' use of the fabric the design still retains marked tracing of the "Terry" edging.

In the early part of these pages, I referred to the fact that the origin of many important inventions and manufactures was lost in the "mist of ages," but here we have an example of one that has passed out of memory whilst its originator is still living: for I venture to say that few indeed of the thousands who daily lounge in their easy chairs on embossed Utrecht velvet would ever suspect that this material issued from the same room in "Baxter House" in which all my first steel experiments were made; and that the same hand which regulated and controlled the fiery steel converter also drew the first few hundred yards of that very beautiful material through the rolls.

| Previous chapter/page | Back | Home | Email this | Search | Discuss | Bookmark | Next chapter |